Transform Your Metalwork Projects with Laser System Technology

If you work with metal-whether you’re a hobbyist, a small business owner, or part of a larger manufacturing team-you know how important it is to get clean cuts, precise shapes, and a professional finish. That’s where laser system technology comes in.

In this article, we’ll show you how laser systems work, why they’re better than many old-school tools, and how they can completely upgrade the way you handle your metalwork projects. Read on.

What is a Laser System for Metalworking?

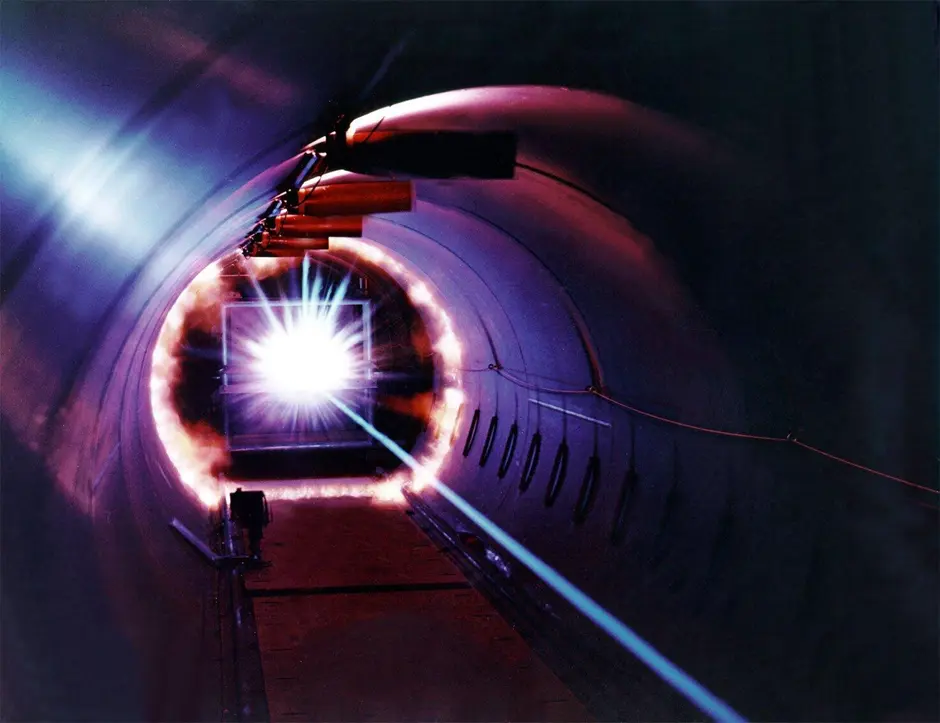

A laser system in metalworking refers to the use of a focused beam of light-typically generated by a CO₂ laser, a fiber laser, or another type of solid-state laser-to cut, engrave, or process metal materials.

These systems are often driven by CNC (computer numerical control) programming, which allows the laser head or workpiece to follow precise, digitally-defined paths. Unlike mechanical tools, the laser is a non-contact method, using concentrated light to melt, vaporize, or blow away material with incredible accuracy.

This means you can accomplish complex tasks such as:

- intricate cut-outs

- clean edges

- minimal post-processing

- tighter tolerances

These are all essential for professional metalwork. Check out a laser cutting company to learn more.

Key Benefits of Laser System Technology in Metalwork

Here are some of the biggest advantages of adopting a laser system:

Superior Precision and Complex Geometry

Laser systems offer extremely fine tolerances and high repeatability. The narrow beam, guided by precise software, enables you to create complex shapes, internal cut-outs, sharp corners, and delicate details that would be difficult or even impossible using traditional tools.

Clean Cuts and Reduced Finishing

Lasers produce smooth, burr-free edges, reducing or even eliminating the need for grinding, sanding, or polishing after cutting. The narrow kerf (cut width) means minimal material is wasted, and the parts come out clean, ready for assembly or finishing.

Minimal Heat-Affected Zone (HAZ)

Laser systems concentrate heat in a very small area, resulting in a reduced heat-affected zone. This minimizes thermal distortion and helps preserve the mechanical and metallurgical properties of the metal-especially important in precision components and thin materials.

Efficiency, Speed, and Material Utilization

Laser cutters are fast, especially with thin to medium-gauge metals. Automation and CNC programming allow for quick transitions between jobs, reduced setup times, and better use of sheet materials thanks to intelligent nesting software.

Versatility in Materials

Modern laser systems can cut and engrave a wide range of metals, including stainless steel, carbon steel, aluminum, brass, and copper. Many systems also handle non-metals like plastics and wood, making them extremely versatile across industries.

Scalability and Design Freedom

Because the system is controlled digitally, switching from one design to another is simple. This enables quick prototyping, small batch runs, and full-scale production-all using the same machine setup. Designers have much greater freedom to innovate.

Limitations and Considerations

Despite its many benefits, laser system technology does have some limitations you should be aware of. Some laser machines struggle with cutting very thick metal, making other methods like plasma or waterjet a better choice for heavy-duty work. The initial cost of buying and setting up a laser system can be quite high, especially for professional-grade equipment.

Certain metals, like copper and aluminum, can be difficult to cut due to their high reflectivity and heat conductivity. Running a laser system requires trained operators who understand the software, material handling, and machine maintenance. Laser cutting can create dangerous fumes and light exposure, so proper safety gear and ventilation systems are essential.

How to Transform Your Metalwork Projects with Laser Technology

To get the most out of your laser system, consider these practical strategies:

Choose the Right Laser System

Select a machine that matches your typical material types, thicknesses, and part sizes. For example, a fiber laser is highly efficient for cutting metals and requires less maintenance than CO₂ systems.

Use CAD/CAM and Nesting Software

Leverage powerful software tools to design parts and arrange them efficiently on your material sheets. Smart nesting reduces waste and increases throughput.

Design for Laser Cutting

Take advantage of the design freedom laser systems offer. Incorporate intricate shapes, decorative elements, or interlocking parts that would be impractical with traditional methods.

Optimize Cutting Parameters

Fine-tune settings such as beam power, speed, and assist gas to get the cleanest cuts. Proper setup minimizes burrs and reduces the need for post-processing.

Maintain Material Quality

Use clean, flat, and debris-free materials to ensure consistent results. Contaminants or surface irregularities can affect cut quality and lead to inconsistent edges.

Implement Proper Safety Measures

Install appropriate fume extraction, shielding, and emergency shutoff systems. Operators should wear protective eyewear and be trained in safe operation practices.

Measure Cost vs. Value

While initial costs can be high, factor in the long-term savings:

- faster production

- lower labor costs

- better material use

- higher quality output

Often, the investment pays for itself in the form of increased capacity and reduced rework.

Explore Engraving and Branding

Use your laser system not only for cutting but also for engraving serial numbers, logos, or design features. This adds value and customization to your products.

Stay Current with Technology

Laser systems continue to evolve. Higher-powered fiber lasers, improved cooling, faster software, and better automation are constantly hitting the market. Stay updated to keep your shop competitive.

Real-World Impact: What You Can Achieve

Imagine running a small fabrication shop where cutting was once time-consuming, inconsistent, and required lots of finishing. With a laser system in place, you can:

Produce precise, repeatable parts with tight tolerances. Cut multiple complex shapes in minutes rather than hours. Reduce material waste through smarter nesting.

Eliminate most post-processing steps like grinding or sanding. Pivot quickly between different jobs or customer designs.

Expand your offerings into custom engraving or artistic metalwork. Increase throughput with less labor input.

The impact on your bottom line is immediate: better quality, faster delivery, and the ability to take on more complex or higher-margin jobs.

Take Advantage of Laser Tech Today

Laser system technology is changing the game for anyone who works with metal. Whether you’re making custom signs, industrial parts, or detailed artwork, a laser system gives you the speed, accuracy, and flexibility to do it better and faster. If you’re ready to take your metalwork projects to the next level, adding a laser system might be the smartest move you can make.

If you want to read more articles, visit our blog.

Also Read-Smart Design at Sea: How Integrated Tech is Optimizing Space and Experience Onboard