The Key Benefits of Using Lubricants in Industrial Equipment Operations

Key Takeaways

- Lubricants significantly reduce friction and wear, ensuring the efficiency and longevity of industrial equipment.

- Proper lubrication improves energy efficiency, protects against corrosion, and minimizes downtime.

- Adopting a proactive lubrication strategy enhances safety and supports long-term cost savings.

Table of Contents

- Introduction

- Reducing Friction and Wear

- Enhancing Equipment Lifespan

- Improving Energy Efficiency

- Preventing Corrosion and Contamination

- Reducing Downtime and Maintenance Costs

- Enhancing Safety in Operations

- Conclusion

Introduction

Industrial equipment is the backbone of manufacturing and production, making its efficiency and reliability crucial for business continuity. The unscheduled breakdown of critical machinery can result in costly downtimes and lost productivity, putting an organization’s ability to meet orders and maintain client relationships at risk. One of the most effective ways to ensure machinery operates at peak performance is through proper lubrication. Regular lubrication routines help keep equipment functioning efficiently and, in turn, enhance output quality and throughput. For companies seeking high-quality products and technical expertise, industrial suppliers in North Carolina offer a range of lubricants and support services tailored to local manufacturing needs.

Lubrication isn’t just a routine maintenance task. It’s a strategic component of equipment management and operational efficiency. Properly selected and applied lubricants support smooth machinery operation, drastically reduce mechanical failures, and lower overall operational costs. They shield machines from the harsh conditions often found in industrial environments, improving both productivity and workplace safety by preventing hazardous incidents caused by equipment malfunction. As such, lubricant selection and usage are essential aspects of an effective preventive maintenance program.

Reducing Friction and Wear

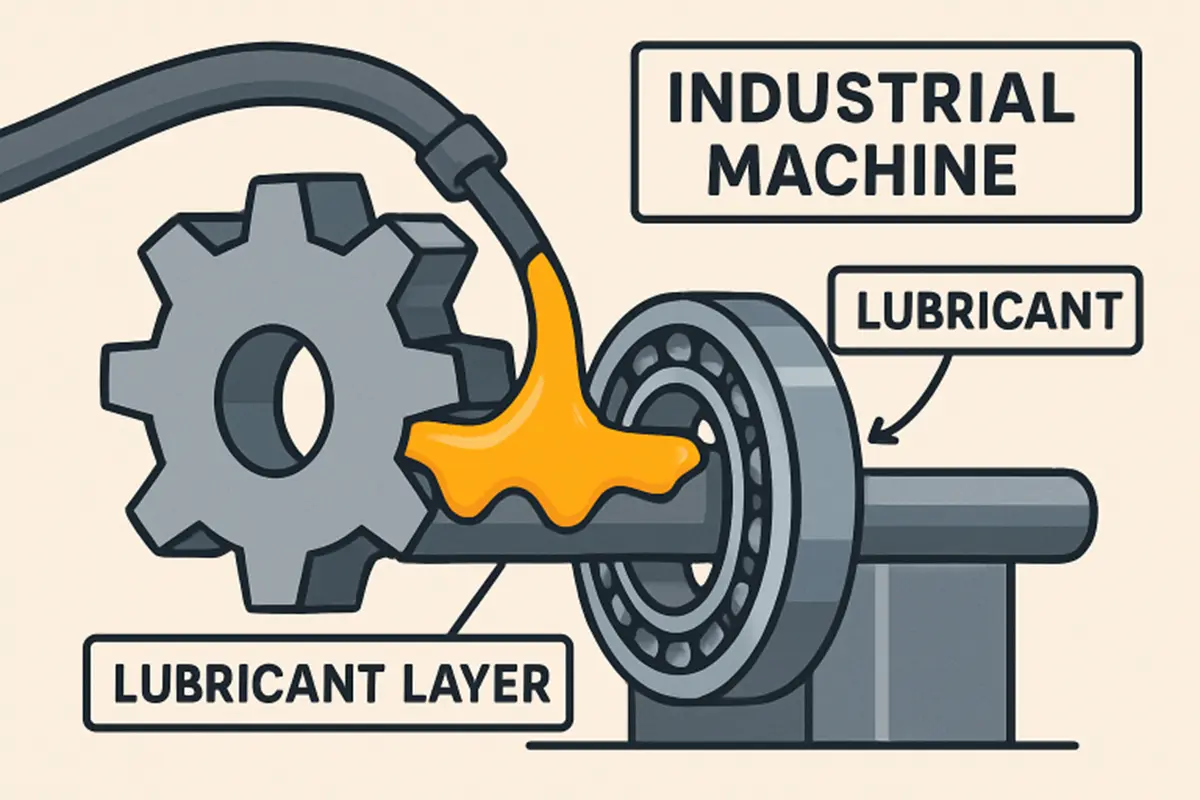

One of the primary purposes of lubricants is to minimize friction between moving parts. In the absence of a lubricant, heavy machinery components such as gears, shafts, and bearings can grind against one another, leading to accelerated deterioration and, ultimately, complete breakdown of critical components. When heavy machinery operates without sufficient lubrication, direct metal-to-metal contact occurs, leading to rapid wear and potential breakdown. High-performance lubricants create a thin film between surfaces, protecting them from damage and facilitating smooth movement by allowing parts to glide rather than grind. This means machines can operate more quietly, with reduced vibration and heat generation, which further limits the risk of mechanical failure. According to Machinery Lubrication magazine, using the proper lubricant can extend the life of machine components by up to 40%, resulting in significant cost savings over time for any business that relies on industrial equipment for core operations.

Reduced friction not only lowers the likelihood of component failure but also means that engines, pumps, conveyor belts, and other moving parts require less energy to function, improving the overall efficiency of industrial processes. This decreased energy consumption manifests in both operational savings and improved environmental performance, as properly lubricated machines tend to produce fewer emissions and generate less waste heat.

Enhancing Equipment Lifespan

The lifespan of any piece of industrial equipment hinges on how well its internal components are protected and maintained. Lubrication serves as a vital defensive measure, ensuring that critical parts do not endure unnecessary stress or wear from friction and abrasive contaminants. Proper lubrication ensures that gears, bearings, and other moving parts don’t grind against one another, thus preventing premature failure and unexpected downtime. Over time, this approach reduces the frequency and severity of repairs, helping equipment retain higher operational value and usefulness. A systematic lubrication plan often includes scheduled inspections, oil changes, and routine monitoring of lubricant condition, which collectively lead to optimized equipment utilization and a better return on investment.

Prioritizing machine longevity through preventive lubrication programs not only benefits overall plant productivity but also helps companies budget more effectively by reducing unexpected machinery replacement costs and capital expenditures. Consistently cared-for equipment can function effectively for decades rather than years, giving organizations a competitive edge in both output quality and reliability.

Improving Energy Efficiency

Friction is one of the most significant contributors to energy loss in industrial operations, often going unnoticed until inefficiencies start affecting the bottom line. Lubricants significantly reduce internal resistance, making it easier for machinery to perform its designated tasks without overexertion. As noted by the U.S. Department of Energy, optimizing energy consumption in manufacturing not only reduces operating expenses but also lowers carbon emissions, supporting broader sustainability goals and compliance with environmental regulations.

Improved energy efficiency enables businesses to scale operations sustainably while maintaining profitability—even in high-demand production environments. Studies have shown that by minimizing friction-related energy losses, companies can achieve a tangible drop in utility costs, often resulting in substantial annual savings. By investing in proper lubrication and monitoring systems to detect lubricant degradation early, companies not only lower their utility bills but also contribute to global efforts to build a greener industrial sector with reduced energy waste and environmental impact.

Preventing Corrosion and Contamination

Industrial environments expose equipment to moisture, chemicals, dust, and other corrosive agents that can severely degrade metal components if left unchecked. These harsh conditions can quickly rust or corrode exposed parts, leading to malfunction or the need for premature replacement. Lubricants act as a protective shield, forming a barrier on metal surfaces that prevents rust and corrosion. They also serve as a medium for carrying away contaminants—such as dirt, metal shavings, and chemical residues—to filters or separators. This process not only keeps the machine’s insides cleaner but also preserves the integrity of seals and gaskets over longer periods.

Without this crucial layer of protection, corrosion could rapidly spread across machine components, resulting in frequent downtime and extensive, costly repairs. Adequate lubrication thus forms a proactive defense against both internal and external sources of contamination, safeguarding equipment reliability and performance even under the harshest operating conditions.

Reducing Downtime and Maintenance Costs

Machinery breakdown is one of the leading causes of lost production, missed deadlines, and unplanned expenses. Even a brief disruption in equipment operation can cascade through supply chains and disrupt customer commitments. Lubricants significantly reduce the incidence of unscheduled repairs by minimizing wear-related failures and extending the period between routine maintenance requirements. With fewer interruptions, industrial plants enjoy improved productivity and enhanced scheduling reliability, allowing them to meet deadlines and maintain client trust.

Moreover, a solid lubrication regime simplifies maintenance routines, enabling teams to spot issues before they escalate. Early identification of lubricant degradation through practices such as regular oil sampling and analysis can reveal potential problems, enabling timely interventions that prevent major breakdowns. This approach saves money on emergency fixes, minimizes the labor required for reactive repairs, and extends maintenance intervals, helping facilities get the most value from both their machinery and their maintenance resources.

Enhancing Safety in Operations

Well-lubricated equipment is far less likely to experience malfunctions such as jams, overheating, or seizing—all of which could pose serious threats to workers’ safety. A smooth-running machine not only performs better but also significantly reduces the dangers associated with unpredictable mechanical behavior. Lubricants ensure that machines operate within designed parameters, preventing sudden mechanical failures that could result in accidents or injuries involving trap points, flying debris, or fire hazards.

A safer work environment leads to higher morale, increased productivity, and reduced downtime due to workplace incidents. Many industrial accidents and even large-scale facility crises are traced back to overlooked maintenance, particularly lubrication lapses, underscoring the critical role of lubrication in comprehensive facility safety protocols and OSHA compliance.

Conclusion

Incorporating a comprehensive lubrication strategy into industrial equipment management delivers multifaceted benefits: lower friction and wear, longer equipment life, improved energy efficiency, corrosion prevention, reduced maintenance costs, and safer workplaces. As industrial operations continue to evolve in complexity and scale, prioritizing proper lubrication ensures that investments in machinery yield ongoing returns in reliability, productivity, and cost-effectiveness, providing a foundational pillar for operational success across industries.