Comprehensive Guide to Air Compressors: Types and Applications

Table of Contents

- A Quick Look at Air Compressors

- Basic Working Principles

- Main Types of Air Compressors

- Choosing the Right Compressor for Your Needs

- Air Compressor Applications Across Industries

- Energy Efficiency and Environmental Considerations

- Maintenance Best Practices

- Final Thoughts

A Quick Look at Air Compressors

Air compressors are essential machines that transform power into potential energy stored in compressed air. These devices offer energy on demand through various mechanisms for various tools and industrial processes. The fundamental purpose of an air compressor is to deliver a steady supply of pressurized air for applications such as inflating tires, powering pneumatic tools, spray painting, and much more. For those focused on quality and reliability, https://cbeuptime.com/ provides access to advanced air compressor solutions.

The history of air compressors dates back to ancient civilizations, where bellows were used to intensify fires. Over the centuries, technology has evolved from manually operated devices to complex systems powered by electricity or combustion engines. This evolution reflects the growing need for more efficient, powerful, and adaptable compressed air technologies.

At its core, an air compressor draws in atmospheric air, reduces its volume, and increases its pressure. This energy-rich compressed air is stored in a tank and released as required for various applications. There are two primary means of air compression:

- Positive Displacement Compressors: These units work by mechanically reducing the volume of air, trapping a fixed amount, and compressing it in a chamber. Examples include reciprocating (piston) and rotary screw compressors.

- Dynamic Displacement Compressors: These types use rapidly rotating blades to impart velocity to the air, converting it to pressure, as seen with centrifugal and axial compressors.

Key components common to most air compressors include the intake valve, compression chamber, power source, motor, and storage tank. Each part plays a vital role in ensuring safe and efficient operation.

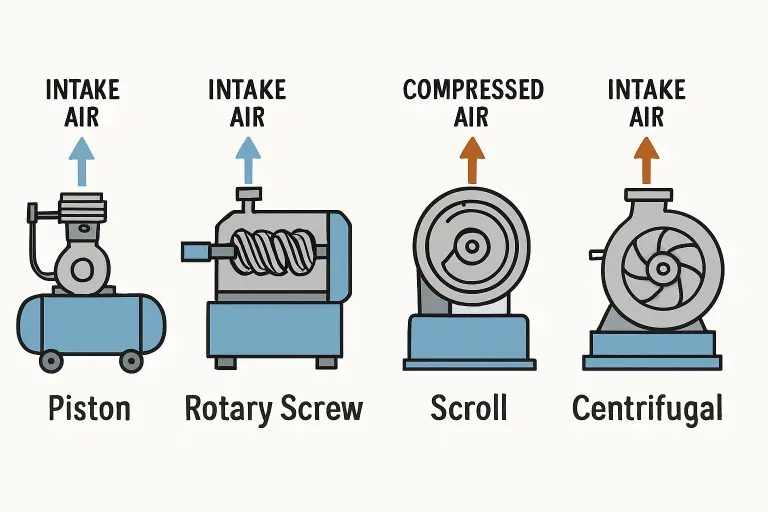

Main Types of Air Compressors

- Reciprocating Air Compressors: These are positive displacement compressors that use pistons driven by a crankshaft. They are ideal for intermittent use and provide high pressure for tasks such as powering pneumatic tools or inflation devices.

- Rotary Screw Compressors: Preferred in industrial settings, these machines use two rotating screws to compress air. Their continuous operation and efficiency make them suitable for large factories and workshops.

- Scroll Compressors: These use two spiral-shaped elements to compress air smoothly and quietly. They are compact, reliable, and often found in the medical and electronics industries, requiring clean, oil-free air.

- Axial and Centrifugal Compressors: These dynamic compressors are utilized in applications demanding high flow rates, such as jet engines, large refrigeration units, and power plants.

Choosing the Right Compressor for Your Needs

Selecting the best air compressor hinges on several factors. Key considerations include the desired pressure (measured in PSI), air delivery (CFM), duty cycle (how long it needs to run before resting), and the nature of your application—whether home improvement, automotive, or industrial manufacturing.

Smaller portable units may suffice for residential purposes, while industrial operations require larger, stationary compressors built for endurance and volume. Weighing cost and energy efficiency will impact upfront investment and ongoing operational expenses.

Understanding these variables allows for an informed purchase that balances performance, efficiency, and longevity.

Air Compressor Applications Across Industries

- Manufacturing and Automotive: Compressors are indispensable for powering assembly line tools, painting, and testing automotive components.

- Healthcare Sector: Compressed air powers dental equipment and sterilization systems, protecting patient safety.

- Agriculture and Construction: Farmers use compressors for crop spraying and machinery maintenance, while construction crews rely on them for pneumatic tools and concrete spraying.

- Food and Beverage Processing: Compressors drive efficiency and food safety by automating packaging, conveying, and product filling.

Energy Efficiency and Environmental Considerations

As energy costs rise and regulations tighten, air compressors are being designed with efficiency in mind. Innovations include variable speed drives, heat recovery systems, and advanced controls to minimize idle time and reduce energy losses.

However, compressed air systems can be energy-intensive, accounting for up to 10% of total industrial electricity consumption. Attention to proper maintenance and the adoption of efficient technologies are crucial to minimizing environmental impact.

Future trends point toward improved monitoring, predictive maintenance, and continued improvements spurred by environmental regulations and government energy standards.

Maintenance Best Practices

- Routine Checks: Inspect hoses, fittings, and filters for leaks or wear and tear.

- Preventive Steps: Drain moisture from tanks, clean or replace air filters, and monitor oil levels where applicable.

- Common Problems: Reduced pressure, overheating, or excessive noise often stem from neglected maintenance or worn parts.

- Safety Measures: Always depressurize the system before maintenance, wear protective gear, and follow the manufacturer’s guidelines for operation and repairs.

Consistently applied maintenance routines extend system longevity, prevent costly breakdowns, and uphold workplace safety.

Final Thoughts

Air compressors are versatile, essential machines that power various applications across industries, from manufacturing and healthcare to agriculture and food processing. Understanding the different types of compressors, their key components, and the specific requirements of your tasks ensures optimal performance and efficiency. Energy-conscious operation and regular maintenance are crucial for prolonging equipment life, reducing costs, and minimizing environmental impact.

Also Read-How Technology is Shaping Online Mental Health Services