Air Lubricator Essentials: What B2B Buyers Should Know Before Installing

Pneumatic systems pump life into lots of factory floors, and if they stumble, so does the entire line. A small gadget called the air lubricator sneakily keeps those pistons happy while most folks are busy watching bigger parts. Whether you’re a buyer working with a supplier like Omchele or a maintenance pro checking stock, knowing what this gizmo does and why it matters lets you act fast and spend your budget well.

The rest of this post breaks down how the device ticks, names the must-have features, and hands out installation tips that even rookies can follow without a headache.

What Is an Air Lubricator and Why Is It Needed?

Picture the air lubricator as a tiny oil can that works on compressed air instead of squeaky hinges. It meters lubricant into the flow so pistons, wrenches, and valves slide rather than grind, saving you costly surprises and downtime.

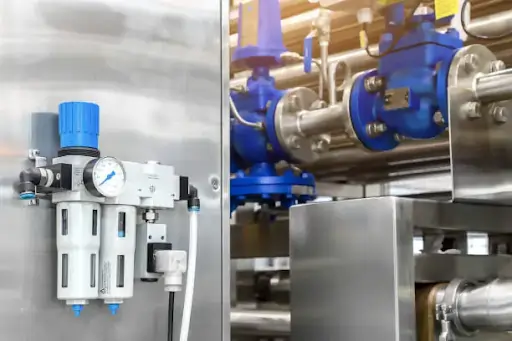

Industrial models run 24/7, shrug off heat, and fit right into the FRL (Filter-Regulator-Lubricator) stack most shops already wire up.

Choose the Right Lubricator, Boost Lifespan

Picking a quality air lubricator and buying it from a trusted supplier-like Omchele-may quickly save you the hassle of blown pistons and flat-out dead compressors. The right mist keeps costly pneumatic gear running smoothly longer.

How Air Lubricators Work

At their core, these tools mist oil into the compressed air moving through the lines. Picture a tiny delivery service that sprays micro-droplets where they’re needed most.

- Oil-Fog Models send out bigger droplets that stick around short runs or single tools. They do the job when the circuit is small and straightforward.

- Micro-Fog Versions break the oil down to a near-invisible cloud that can ride the line for many feet. Those setups shine in plants with twisting piping or multiple stations.

Every lubricator has an oil reservoir, a flow-control dial, and usually a glass dome so you can eyeball the mist without guessing.

Get the unit plumbed right, and the oil is atomized just before it slips into the pneumatic network. Miss that step, and the lubricant can settle out of the stream.

If the system runs dry, friction spikes and parts grind away like sandpaper. That sprint to save a buck today often costs ten times more when the valve or cylinder quits tomorrow.

Why Consider an Air Lubricator?

Hooking a good-quality air lubricator into your compressed-air setup does more than spray a little oil; it hands you a measurable edge.

Longer Equipment Life

Friction eats metal for breakfast. A steady mist of lubricant cuts that friction, keeps valves and motors cool, and lets them clock thousands of extra hours before retirement.

Sharper System Efficiency

Slower-moving gears waste energy. Greasing the works pulls that drag out of the equation, so the whole system runs smooth, quick, and with noticeably lighter power bills.

Less Downtime

Sticking cylinders costs money-and headaches. A reliable lubricator keeps moving parts loose, letting hectic production lines breathe easy instead of sputtering to a halt.

Better Tool Behavior

Pneumatic wrenches in a body shop don’t wait for permission to seize. Constant oiling keeps torque steady, so guns stop stripping bolts and start calling it a shift on schedule.

What to Check Before You Buy

Not every lubricator will bond with your setup, so you can’t grab the first one that catches your eye. Pay attention to cause-and-effect:

Flow Rate Match

If your line pushes 600 SCFM and the unit tops out at 400, odds are good you’ll wind up with inconsistent mist and fading pressure at the worst possible moment. Outgrow an undersized model once and you’ll never make that mistake twice.

Operating Pressure

Look at the pressure dial. Most inline lubricators work well between 0.5 and 10 bar, but specific tasks sometimes push those numbers higher or lower. Double-check the sticker on your unit or the spec sheet before plugging it in.

Lubricant Type

Grab the oil that the manufacturer lists. Trying to save a buck with a different fluid can make seals swell, lines clog, and pumps weep. Stick to the tested brand and viscosity, even if that means waiting on a special order.

Distance to Lubricated Equipment

Micro-fog models shine when the run to the tools stretches more than a couple of meters. The mist they create stays fine over distance, while dripper-style units risk puddling before the air motor ever sees it. For short runs, a simple drip system is usually plenty.

Maintenance Accessibility

Pick a bowl you can actually peek through. A big sight glass lets you spot low oil from ten feet away. Easy-fill ports and built-in shut-offs shave minutes off weekend servicing. Exhaust valves that jam halfway closed add hours no one planned for.

When B2B clients team up with Omchele, they’re not just ordering metal. Engineers walk them through sizing and placing the right lubricator for whatever automation jungle they’ve built. Technical support doesn’t clock out when the shipment does.

Common Mistakes to Avoid

Even a top-shelf air lubricator will stall out if you wire it wrong or drown it in oil. Learning the traps ahead of time saves a lot of headache later.

- Over-lubrication: Slopping in extra fluid doesn’t magically polish moving parts. It usually spells sticky deposits that turn valves into door stops.

- Incorrect Positioning: Always hang the lubricator after the filter and regulator. Backward plumbing robs the machine of clean, steady pressure and leaves the lubricator sitting useless.

- Contaminated Oil Debris, water, or rust particles sneaking into your oil supply will scratch metal surfaces and muck up the internal parts of lubricators and linked gear.

- Skipping Oil Refills Letting a lubricator run dry instantly cancels its whole purpose and speeds up wear like a sandpaper strip rubbing metal.

Keeping a savvy automation partner such as Omchele by your side helps crews dodge these mistakes and get grease systems set up right the very first time.

Air Lubricators in Action

Manufacturers reach for air lubricators in all kinds of workplaces, and the devices show up in:

Automotive Lines

Fast-moving assembly cells depend on clean, oiled air to keep impact guns, robots, and pneumatic clamps from stalling mid-task.

Food & Beverage Packing

Direct oil hits are a no-go in splash zones, but back-room conveyors and case sealers still use lubricators that meet strict cleanliness rules.

CNC and Metal Shops

Pneumatic vises and turret slides grind to a halt without a steady mist, so shops bolt a lubricator to keep chips from jamming the works.

Material Handling

AGVs, pick-and-place arms, and lift tables glide better when their air supply is slick, cutting downtime and saving on repairs.

A well-tuned air lubrication system can do more than keep a machine’s guts humming; it trims maintenance hours and slashes the bill for parts. Firms that team up with veteran providers such as Omchele tend to see those savings show up pretty quickly.

Best Practices for Maintenance and Performance

Peak performance doesn’t just happen by luck. Following a few straightforward habits keeps the system working smoothly:

- Cruise by every week or so to eyeball the oil level, then top off with the specified grease. A small check today can spare a big headache tomorrow.

- Glance through the sight dome and watch for that fine mist. If the spray looks lazy, something inside the unit may need attention.

- Dust and residue are sneaky; wipe the casing and drain traps whenever you can. A clean unit breathes easily and runs longer.

- Loose hoses and cracked seals let pressure sneak away faster than you think. Snug up fittings and swap out worn gaskets at the first sign of trouble.

- New hires benefit from a quick session on flow-rate tweaks. Pouring too much oil is just as harmful as none at all.

Buying direct from Omchele usually bundles the hardware with easy-to-read manuals and real-world tips, so there’s less guesswork down the road.

Conclusion

Small in stature but large in role, an air lubricator keeps an industrial air system from grinding to a halt. Engineers and procurement teams looking to stretch uptime should treat this component as a VIP, not an afterthought. Choose carefully, install correctly, and watch performance soar.

When you team up with a veteran supplier such as Omchele, your system orders land on time, fits perfectly, and works with the right oils. Inside modern smart factories, tiny parts suddenly seem huge because they keep production on schedule.

Read more: Simple Ways to Sell a House Fast: What Today’s Homeowners Need to Know – SizeCrafter

Empowering Student Authors: Free Publishing Strategies – SizeCrafter

How Smart Towing Practices Are Transforming Heavy-Duty Hauling – SizeCrafter